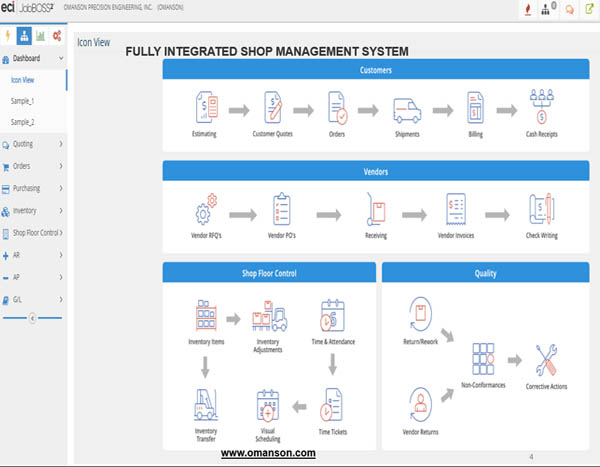

We Are Here To Deliver Quality and Precision

Omanson Precision Engineering strives to deliver the services and value that meet or exceed our customer’s requirement. Omanson Precision Engineering commits to comply with all applicable requirements and to constant improvement by training its personnel, upgrading equipment and eliminating nonessential practices.

CERTIFICATE OF REGISTRATION

• ISO 9001:2015/AS9100 Rev D

• ITAR Registered

• DLA Registered

• BOEING COMMERCIAL Registered

• BOEING DEFENSE Registered

• LOCKHEED Registered

• ITAR Registered

• DLA Registered

• BOEING COMMERCIAL Registered

• BOEING DEFENSE Registered

• LOCKHEED Registered

NACIS CODES

• 332710 Machine Shops

• 332999 Fabricated Metal Mfg

• 336412 Aircraft Engine & Parts

• 336413 Aircraft Auxiliary Equipment

• 336419 Guided Missile and Space Equipment

• 332999 Fabricated Metal Mfg

• 336412 Aircraft Engine & Parts

• 336413 Aircraft Auxiliary Equipment

• 336419 Guided Missile and Space Equipment